Australian gear manufacturer, Ronson Gears, is a manufacturing industry success story and, as it prepares to celebrate 60 years in business, this family-owned Victorian company vows to continue its long established focus on quality and customer service to ensure its continued prosperity.

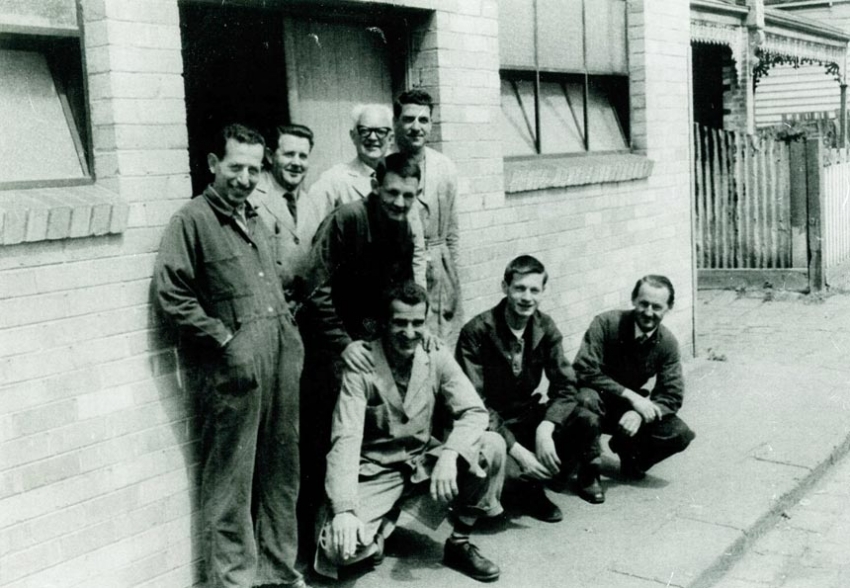

When Ronald New opened a small workshop in suburban Melbourne in 1954, he set about providing a quality service that set the foundations for the modern company. Ronald named the company Ronson – in the hope that one of his son’s would carry on the business and today, brothers Gordon and Terry New agree that his foresight was, on many levels, uncanny.

According to Managing Director, Gordon New, Ronald’s focus on quality and customer service earned the small company a reputation for innovation and excellence, which has continued on into the present.

When Gordon and Terry New took over the company’s management, they realized the importance of a global outlook – in all areas of the business – and they insist that this international focus has had the most significant impact on shaping Ronson Gears’ growth ever since.

It was this international outlook that led to Ronson Gears’ decision to invest in state-of–the-art equipment, which has been a cornerstone of the company’s sustained success.

According to Gordon, the purchases that stand out were the Gleason 125 CNC Hobber in 1996, the first of two CNC Hofler Gear Grinders in 2002 and the Wenzel GearTec gear measuring machine in 2004.

These investments gave Ronson Gears the ability to deliver standards of service not previously available in Australia and the subsequent recognition from customers cemented their international reputation as a quality gear manufacturer. At the same time, there’s been broader recognition for the company within the industry through formal accreditation processes.

The most recent recognition happened earlier this year, when Ronson Gears was awarded accreditation to AS9100C Quality Management System Standard (Aerospace), paving the way for its expansion into new markets internationally. According to Gordon, the accreditation remains one of the company’s major achievements in terms of its potential benefits.

“The AS 9100C accreditation is international recognition of the standards we work to,” Mr New said. “and we’re very proud of the fact that we earned our first formal accreditation – (the) ISO9001 – back in 1998.”

The same sustained effort that earned the company these formal accreditations is evident in Ronson’s continual improvement (CI) program. With the assistance of the Federal Government’s Department of Industry the company is about to commence the Supplier Continual Improvement Program (SCIP). The program aims to accelerate the competitiveness and raise the performance of individual Australian companies.

The Program follows on from the company’s other CI initiatives that saw it again work with the Government. These saw the introduction of Lean Manufacturing principals as well as other strategic business initiatives that have seen outstanding results that have benefited Ronson’s customer base. It also coincided with being awarded the “Significant Achievement Award” in 2013 as part of the Endeavour Awards.

Another positive outcome of the company’s international focus has come from Gordon News’ involvement in various international industry organizations.

Gordon served on the board of the international industry professional organization, the American Gear Manufacturers Association (AGMA), for 4 years from 2009 until 2013 and has represented Ronson Gears at various industry meetings and events all over the world, speaking at conferences in China, Japan, the USA and Germany. Ronson Gears is a long time associate member of Eurotrans, the European Committee for Power Transmission Engineering and has firm relationships with associate companies in Europe, Great Britain, Japan, New Zealand and USA.

Today, Ronson Gears strives to ensure every machinery purchase, every customer order and every decision is tailored towards the company’s and customer’s future well being.

As part of its strategic planning, Ronson Gears has recently commenced a Succession Plan which sees long standing and proven key staff joining the management team to guide the company’s future direction.

Everything is in place for this company to continue to set itself apart as a quality supplier on the international stage. Visit Ronson Gears at www.ronsongears.com or email enquiries@ronsongears.com.au

Visit Ronson Gears at www.ronsongears.com

For interviews or further information contact:

Gavin New gavin.new@ronsongears.com.au M: +61 400 958 722; T: +61 3 9555 9822

or

Gordon New gnew@ronsongears.com.au; M: +61 408 388 968; T: +61 3 95559822

Background information

Ronson Gears’ technologically advanced gear manufacturing equipment is used throughout the gear manufacturing process including: CNC Machining; CNC Gear Cutting; CNC Gear Grinding; CNC Gear Measurement, and CNC Gear Tool Sharpening.

Ronson Gears supplies machined components, gears and assemblies to Raytheon, Land Rover, Boeing Defence Systems and Lockheed Martin in the Aerospace and Defence industries. It supplies spur, helical and internal gears and gear racks to major Australian miners for underground and above ground mining applications, transport and industrial applications including waste management, construction, water management, energy and hoist and crane systems.

From humble beginnings, Ronson Gears is now a leading manufacturer of machined components and gears. Proudly Australian with an international reputation for quality and first-class customer service, Ronson Gears manufactures machined components and gears for diverse industries including aerospace, agriculture, automotive, defence, energy, medical, mining and rail.

It has the capacity to perform all types of machining including CNC turning, milling and grinding, and the gear cutting and grinding of spur gears, helical gears, internal gears, bevel gears, splines and gear racks amongst many other power transmission products. We can also supply spiral bevel gears through our agreement with KHK Stock Gears, Japan.