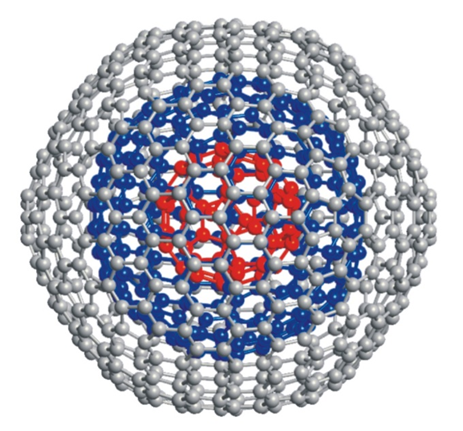

Model of a nano onion

Tool-X is a nano fluid that can potentially change metal cutting dynamics, improve surface finishes and extend tool life.

Mathew Jaster’s article in Gear Technology takes us through a technology that is challenging the status-quo.

Find out how a program that began secretively in the US government can now offer significant benefits to gear manufacturing.

Developed by a group of scientists that think small. In fact, so small – they think nano, nano onions to hone it down still further.

These versatile little things have many applications one of which is nano lubricants. So, what can they do for a gear shop?

These nano-fluids can enhance the thermal conductivity and tribological characteristics in cutting tool applications by reducing friction, lowering tool wear and improving the surface quality of components including gears.

Tool-X also has a lower chemical footprint, so it’s easier for manufacturers to conform to ISO 14001:2015 Standard.

Included in the article are two real life case studies that demonstrate the capabilities of this technology that is challenging traditional production processes. 4M Aerospace Operation and General Motors Hobbing Operation both give enough proof points for gear manufacturers to sit up and pay attention, read more.