Yefim Kotlyar and Christoph Donner make the case for a two-probe index inspection for large gears in their article in Gear Solutions.

The validity of inspection methodology is key as gear pitch accuracy is one of the most important characteristics affecting a gear’s performance.

There are two methods of inspection:- single and two-probe. Both provide accurate results for a range of smaller/medium sized gears.

However, their research concludes that the two-probe pitch measuring method is most beneficial for large diameter gears.

The article examines the merits of the two-probe index inspection and also provides a review of the single-probe pitch inspection methodology, breakdown of tooth index characteristics, and a cross-reference of the single and two-probe inspection methods.

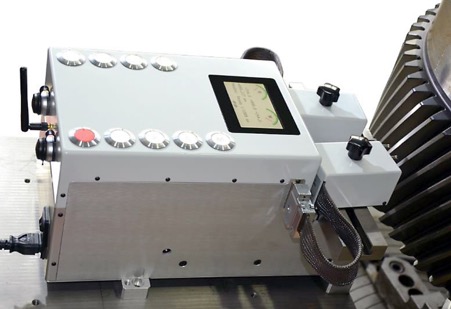

In essence, their findings are that with the two-probe pitch, the inspection quality does not deteriorate with the increase of gear diameter. Also, since the inspection unit is portable, it can check large gears beyond the capacity of traditional universal gear measuring machines. Such portability also reduces processing time and costs.

Details of the research methods, calculations and findings can be found in the link here.