In the world of advanced manufacturing, precision isn’t just preferred—it’s essential. For over 70 years, Ronson Gears has been a cornerstone of Australian industry, providing high-quality gear solutions that power everything from industrial machinery to cutting-edge robotics. As the manufacturing landscape evolves, Ronson Gears continues to play a critical role in enabling innovation, efficiency, and reliability across sectors.

The gears behind the machines

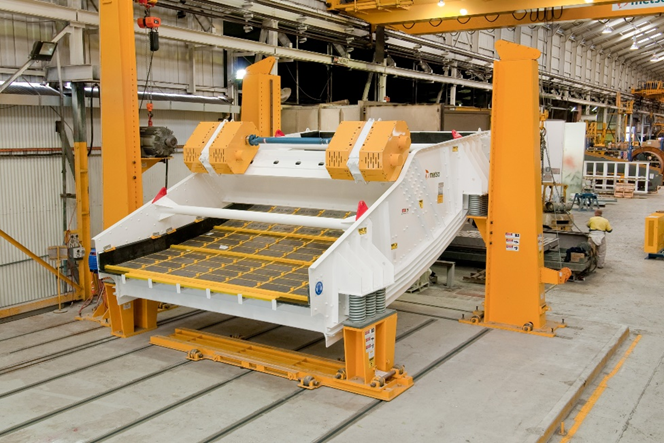

Gears are the silent workhorses of manufacturing. They transmit torque, control motion, and define the performance of machines big and small. From conveyors on factory floors to complex CNC systems, gears underpin modern production. Ronson Gears understands this better than anyone. Our commitment to precision gear engineering ensures that every component meets the exacting standards required for peak performance.

With advanced CNC gear cutting and CNC gear grinding capability, Ronson Gears doesn’t just supply parts—we deliver performance-critical solutions that are tailored to the specific needs of manufacturers.

Supporting Australian manufacturing—and beyond

As the manufacturing sector becomes more automated and globalised, local suppliers that can deliver quality and responsiveness are more valuable than ever. Ronson Gears supports not only Australian OEMs (Original Equipment Manufacturers), but also global clients across outer space, aerospace, defence, mining, rail, and renewable energy industries. Our expertise ensures that complex gear requirements—such as spur gears, splines, bevel gears and helical gears—are manufactured to the most stringent international standards, including AGMA and DIN. Our AS 9100D accreditation allows us to work in sectors such as aerospace that require the most demanding standards.

This technical edge means Ronson Gears contributes directly to manufacturing success stories around the world—helping companies build smarter, more efficient machines that drive productivity.

Enabling innovation through collaboration

What sets Ronson Gears apart is our collaborative approach. We work closely with engineers and product designers from the early stages of development, often helping optimise gear design for manufacturability, longevity, and performance. This partnership approach has helped manufacturers reduce downtime, increase energy efficiency, and extend the service life of critical systems.

By investing in continual training, lean manufacturing principles, and the latest technology, Ronson Gears ensures we remain not just a gear supplier—but a strategic partner in innovation.

Gearing up for the future

As Industry 4.0 continues to transform manufacturing with digital technologies, Ronson Gears is staying ahead by integrating advanced software, automation, and quality systems into our workflow. Ronson Gears invests significant amounts every year to maintain our edge with new machinery and the latest technology. Our ability to adapt and deliver in a fast-changing landscape reinforces their reputation as a trusted name in high-precision gear manufacturing.

Whether it’s supporting traditional manufacturing lines or enabling the next generation of automated systems, Ronson Gears is here to ensure your manufacturing progress and innovation.