Plastic gears are increasingly replacing metal gears in an expanding number of applications. After all, they have a number of advantages; less weight, reduced need for lubrication, cost effective to produce and having significantly better NVH characteristics.

Not that it is all one way. Plastic gears have lower load bearing capacity than their metal counterparts, poorer thermal conductivity, susceptibility to temperature change and lower achievable manufacturing precision.

However, answering demand from customers the NVH credentials of plastic is gaining greater significance.

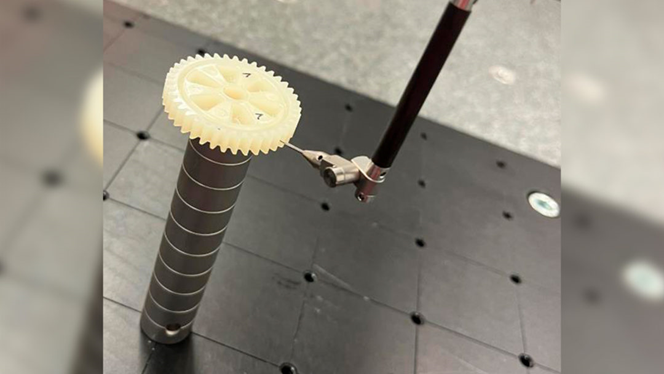

So, an experimental study on the NVH performance of plastic gears in Gear Technology magazine makes interesting reading.

The study, was conducted by Dr.Damijan Zorko, Rok Kalister and Dr.Borut Cerne . They explain their guidelines, methodology, testing conditions, results and discussion in their article below.

In their tests the noise levels for the steel gear pairs were 10dB or higher than those of the plastic gears with much lower vibration generated by the plastic gears.

Gear pairs consisting of one unreinforced and one reinforced gear exhibited a higher meshing stiffness, a lower transmission error resulting in lower vibrations. Full results can be found below.

However, the authors did point out that to their knowledge there are several topics relating to plastic gears still to be studied. Namely, how the NVH in plastic gears increases with wear and the effects of grease on performance. Given the increasing use of plastic gears these assessments will likely be not too far away. In the meantime, these conclusions offer insight. Read more here.