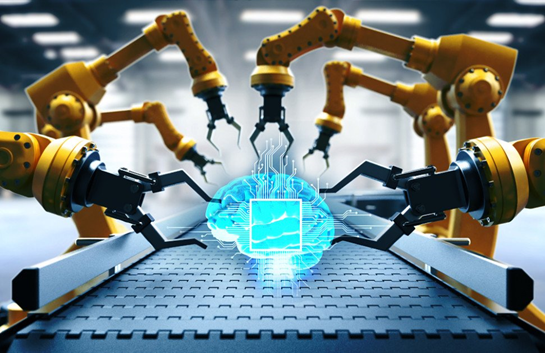

The pace of Artificial Intelligence (AI) implementation has skyrocketed across all industries but was particularly noticeable in manufacturing, according to KPMG – see link here.

93% of industrial manufacturing business leaders say that AI is at least moderately functional in their organisation. 49% of manufacturers say that AI is fully functional at scale.

So how is AI being put to work in manufacturing?

On the Unite AI site, Arkady Sandler, CEO and co-Founder of Docet TI, identifies 7 ways AI is changing manufacturing.

- Predictive Maintenance. Integrating AI programs into software can maintain up-to-the-minute monitoring to detect potential failure points before they arise.

- Quality Assurance. AI can streamline QA steps improving efficiency and costs by aggregating data across all phases.

- Defect Inspection. AI can inspect items much faster and more thoroughly than the human eye.

- Warehouse Automation. From the process of invoices, product labels and vender documentation to using algorithms for optimizing shelving space realising huge ROI.

- Assembly Line Integration and Optimization. AI can quickly and easily sort and structure the entire facility’s aggregated data to provide actionable, practical overview of the entire production process.

- AI-based Product Development and Design. AI is expected to have the most significant impact on product development and design in the next five years.

- SME Utilization. Once upon a time only large corporates had the financial clout to invest in R&D and cutting edge technology. AI has democratised this with smaller manufacturers being able to afford a few small robots and then scale up.

The potential of AI in manufacturing is huge and will likely drive its rapid adoption. Follow this link for the full article.