This article in Gear Solutions magazine by D.Scott MacKenzie, Phd., FASM, continues his range of discussions on non-destructive testing (NDT).

In prior articles, magnetic particle inspection, eddy current inspection, ultrasonic inspection and dye inspection were examined. (You can catch up on these in previous issues of Gear Solutions). Now he turns his attention to the use of Radiography.

So, how helpful are the use of x-rays in detecting and determining the extent of any issues in welds, effects of corrosion and examining how engine components are holding up?

- History

A brief background history of x-rays

- Theory and effectiveness

The article then examines the theory behind them and why they are so effective at detecting issues in various materials

- Equipment size and type

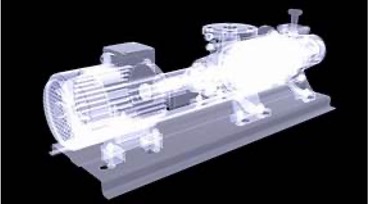

Industrial x-ray equipment comes in a variety of sizes, shapes and energy levels.

- Safety

Obviously a pre-requisite when you are dealing with potentially hazardous radioactive materials. The author stresses the importance of comprehensive training of personnel

- Uses & Applications

What applications is this method of NDT most suited to?

It makes this article well worth an inspection!